The Great Wheel

Household textiles needs of the 18th Century differ little from those of the 21st Century. Households then, as today, require dish towels, table linens, clothing, sheets, and blankets just to name the basics.

In the Chapman-Hall House there is a display of textile tools used to make yarn/thread.

The Chapmans were an average 18th Century family. Even a tradesman, such as the accomplished house-wright that Nathaniel was, would rely on his family to help provide for the needs of the household. The focus of this article is the Great Wheel, also called the Walking Wheel or Wool Wheel.

Both men and women had contributing chores when it came to the textiles needed. For example, the men would shear the sheep and help prepare the fleece for cleaning and grading of the wool.

Once the fleece was sheared, it had to be washed and then graded. Not all the wool would be of equal quality. For example, the wool from the upper shoulders is often considered the best quality in both fine fiber and softness. Wool from the legs and haunches, of lower quality. A fleece can be grouped in up to ten different grades. Before the fiber can be spun it had to be carded, that is brushed to a line and unknot the fibers. It wasn’t until the end of the 18th Century that this hand process was replaced by a machine in America. England was ahead of the Colonies in this field and tried hard to keep the carding machine design all to herself. When using a great wheel, the spinner controls the fiber with one hand. Therefore, it is very important that the fiber be well prepared.

The great wheel, and one can easily see why it is called that, was a common tool for spinning wool during the Colonial era. The term wool wheel referred to the fact that here in New England it was primarily used to spin wool. The name walking wheel refers to the fact that the spinner must walk back and forth, that is, from the front of the wheel backwards, one hand controlling the fibers and the other turning the wheel. The wheel is the mechanism that puts the twist into the fiber.

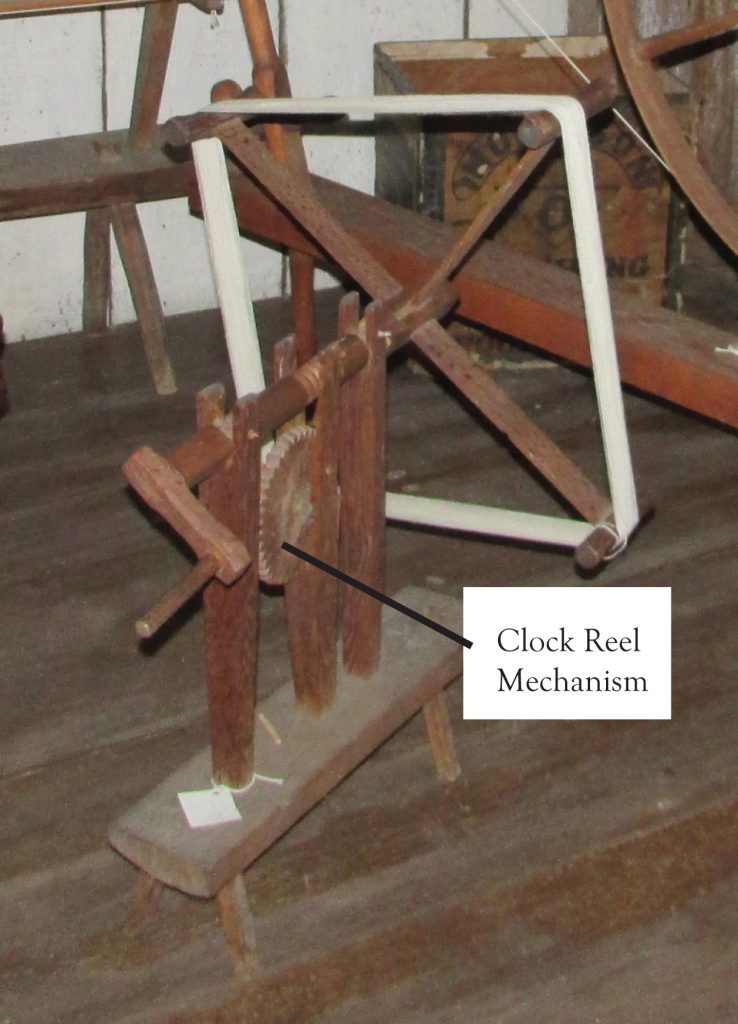

Once spun the yarn had to be measured. A loom could not be set up for weaving until the proper amount of yardage for the piece was ready. This was especially important if the yarn was to be dyed. The clock reel was designed to measure two yards around its four arms.

The term clock comes from the mechanism that would click when 40 turns had been made. Forty turns equaled 80 yards and that measure was known as a knot.

From beginning to end, producing a piece of cloth required a variety of skills.

(Great Wheels can also be found in the Pownalborough Court House)

Louise Miller, LCHA Education Director

Newsletter

Newsletter Join LCHA

Join LCHA Donate Now

Donate Now